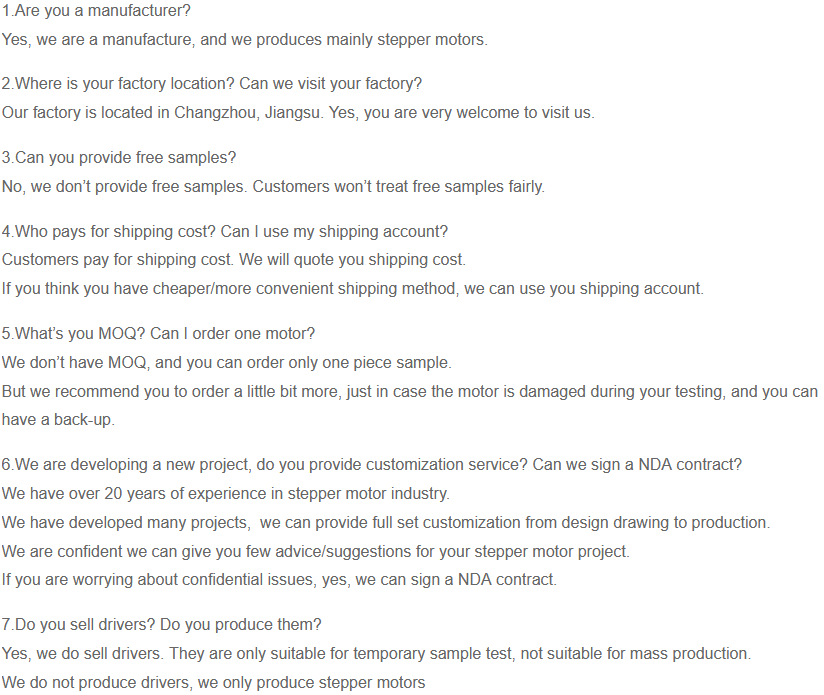

Motor pas cu pas liniar mini Slider de 8 mm, 3,3 V CC, pentru motorul obiectivului camerei

Descriere

VSM0806 este un motor liniar cu micropasuri. Tija șurubului este M2P0.4mm, iar pasul șurubului arborelui de ieșire este de 0.4mm. Șurubul este rotit în poziție împingătoare prin tija șurubului și tija șurubului.

Unghiul de pas de bază al motorului este de 18 grade, iar motorul rulează 20 de pași în fiecare săptămână, astfel încât rezoluția deplasării poate ajunge la 0,02 mm, atingând obiectivul unui control de precizie.

Actuatorul este acționat prin subdiviziune.

Datorită dimensiunilor reduse, preciziei ridicate, controlului ușor și altor caracteristici excelente, acest motor cu micropas este utilizat pe scară largă în camere foto, instrumente optice, lentile, dispozitive medicale de precizie, încuietori automate pentru uși și alte domenii.

Partea de intrare a motorului a FPC poate fi schimbată în forma unui pin de conectare, a unui PCB etc., în funcție de cerințele clientului.

Suportul de montare poate fi înlocuit în funcție de cerințele clientului.

Parametri

| NUMELE PRODUSULUI | MOTOR PAS MICROLINAR DE 8 MM |

| MODEL | VSM0806 |

| FRECVENȚĂ MAXIMĂ DE PORNIRE | 800 PPS min. (la 3,3 V CC) |

| FRECVENȚĂ MAXIMĂ DE ROTAȚIE | 2000 PPS min. (la 3,3 V CC) |

| CUPLU DE STRÂNGERE | 1,5 gf-cm min. (la 500 PPS, 3,3V CC) |

| STRÂNGEREA CUPLULUI | 2,0 gf-cm min. (la 500 PPS, 3,3V CC) |

| CLASA DE IZOLAȚIE | CLASA E PENTRU BOBINE |

| REZISTENȚA IZOLAȚIEI | 300 V AC PENTRU O SECUNDĂ |

| REZISTENȚA IZOLAȚIEI | 50 MΩ (100 V CC) |

| INTERVAL DE TEMPERATURĂ DE FUNCȚIONARE | -10 ~+60℃ |

| SERVICII OEM și ODM | DISPONIBIL |

| NUMELE PRODUSULUI | MOTOR PAS MICROLINAR DE 8 MM |

Exemplu de referință pentru tip personalizat

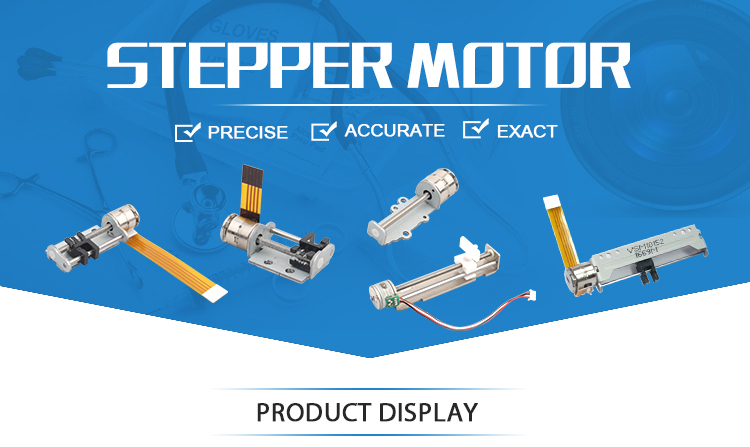

Desen de proiectare

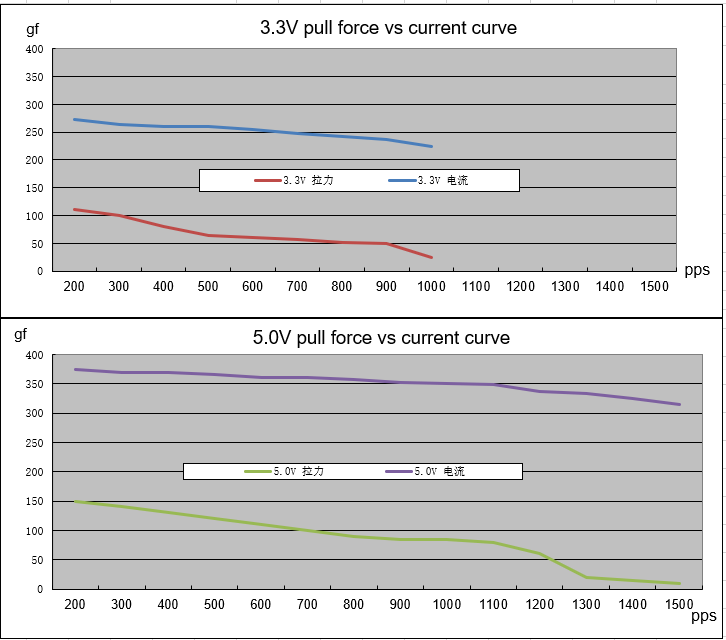

Curba cuplului de testare a motorului Aplicație

MOTOR PASIV VSM0806 Curbă de cuplu (forță de tracțiune)

Condiții de testare:

Mod de acționare: 2-2 faze

Circuit de acționare: acționare bipolară

Tensiune de acționare: 3,3 5 V CC (tensiune de afișare a acționării)

Instrument de măsurare: Sursă de alimentare completă pentru testare, greutate

Rezistență: 20 Ω

Scenarii de aplicare

Serviciu de personalizare

Designul motorului poate fi ajustat în funcție de cerințele clientului, inclusiv:

Diametrul motorului: avem motoare cu diametrul de 6 mm, 8 mm, 10 mm, 15 mm și 20 mm

Rezistența bobinei/tensiune nominală: rezistența bobinei este reglabilă, iar cu o rezistență mai mare, tensiunea nominală a motorului este mai mare.

Designul suportului/lungimea șurubului de acționare: dacă clientul dorește ca suportul să fie mai lung/scurt, cu un design special, cum ar fi găurile de montare, acesta este reglabil.

PCB + cabluri + conector: Designul PCB-urilor, lungimea cablului și pasul conectorului sunt reglabile, putând fi înlocuite în FPC dacă clienții solicită.

Informații despre timpul de livrare și ambalare

Timp de livrare pentru mostre:

Motoare standard în stoc: în termen de 3 zile

Motoare standard indisponibile: în termen de 15 zile

Produse personalizate: Aproximativ 25~30 de zile (în funcție de complexitatea personalizării)

Timpul de livrare pentru construirea unei noi matrițe: în general aproximativ 45 de zile

Timp de livrare pentru producția de masă: în funcție de cantitatea comenzii

Ambalaj:

Probele sunt ambalate în burete de spumă cu o cutie de hârtie, expediate prin expres

Producție în masă, motoarele sunt ambalate în cutii ondulate cu folie transparentă la exterior. (transport pe calea aerului)

Dacă este expediat pe mare, produsul va fi ambalat pe paleți

Metodă de livrare

Pentru mostre și transport aerian, folosim Fedex/TNT/UPS/DHL.(5~12 zile pentru serviciul expres)

Pentru transportul maritim, folosim agentul nostru de transport maritim și expediem din portul Shanghai.(45~70 de zile pentru transport maritim)

FAQ